Round Duct Cfm Chart

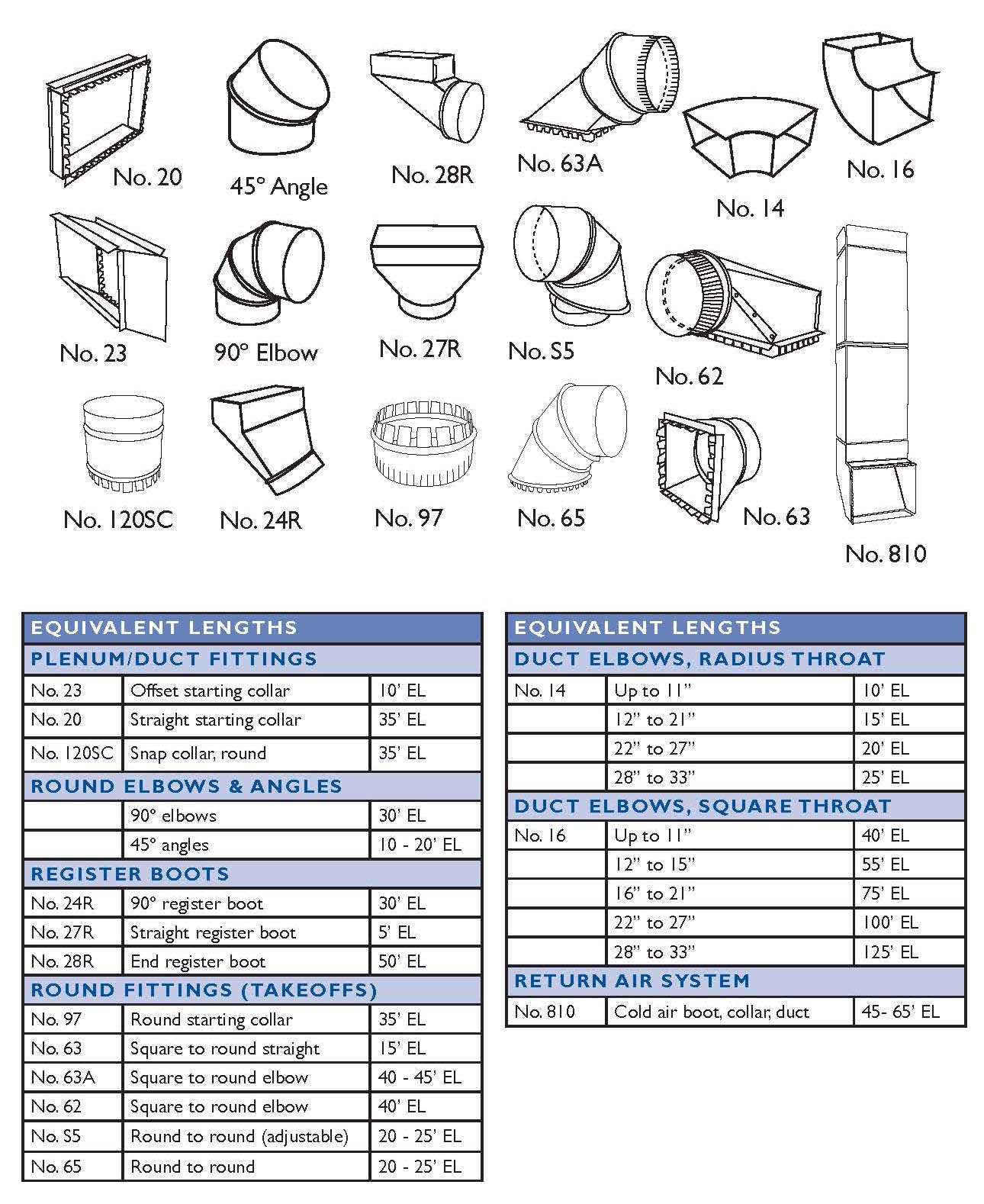

63 square to round straight 15 el no.

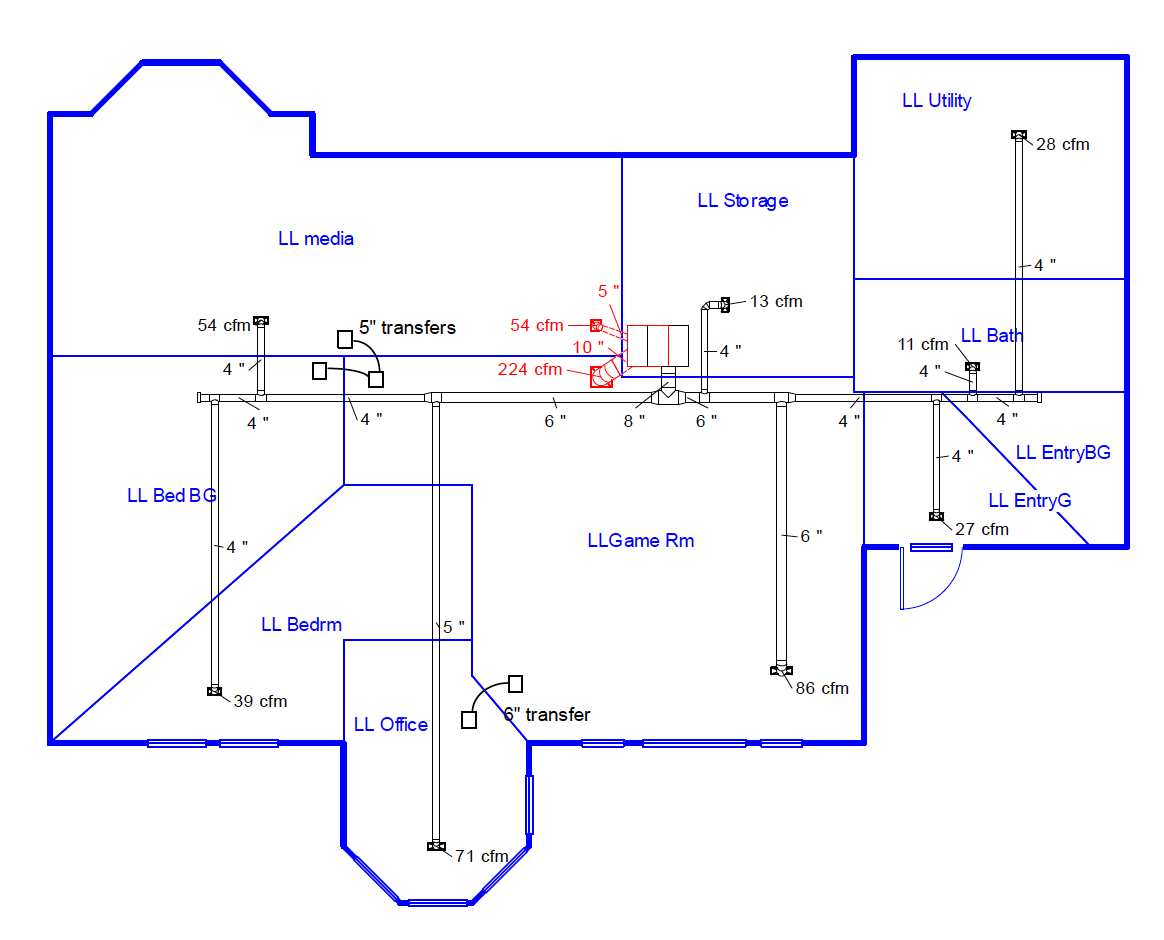

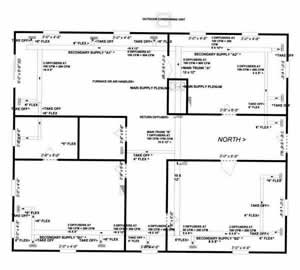

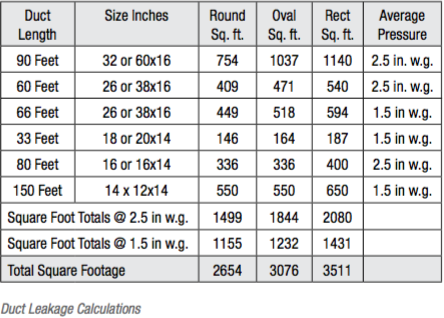

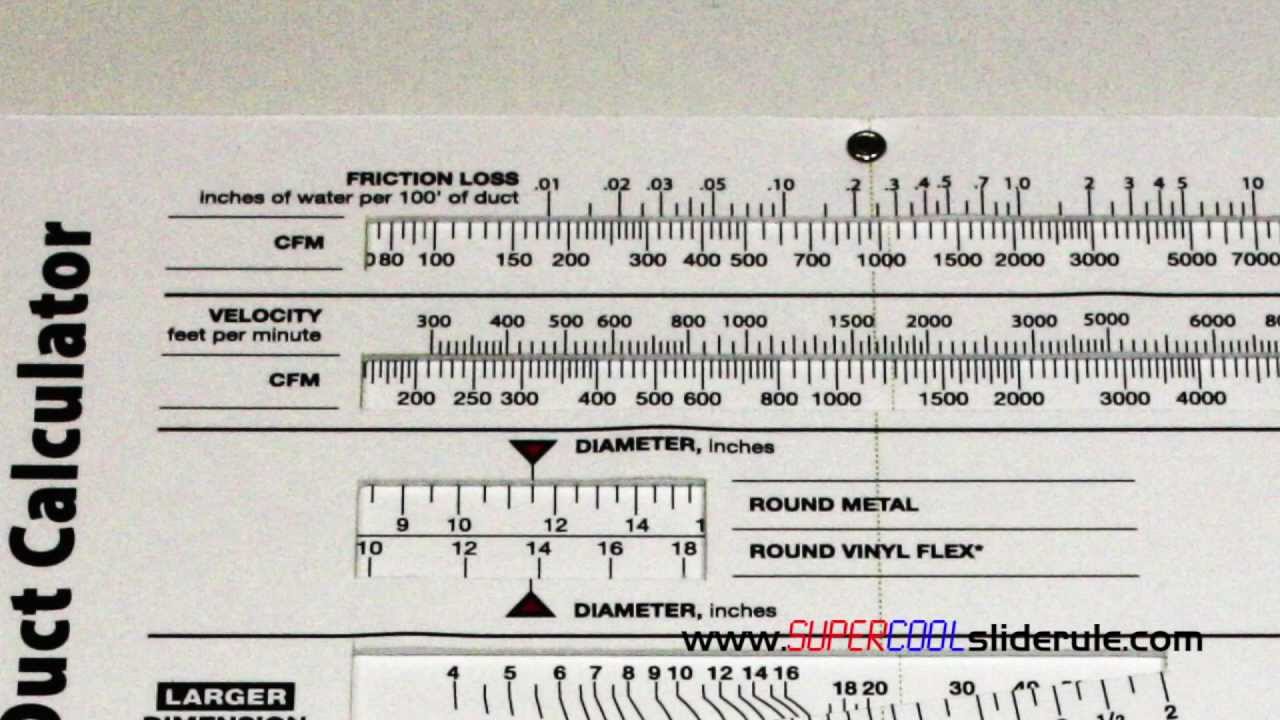

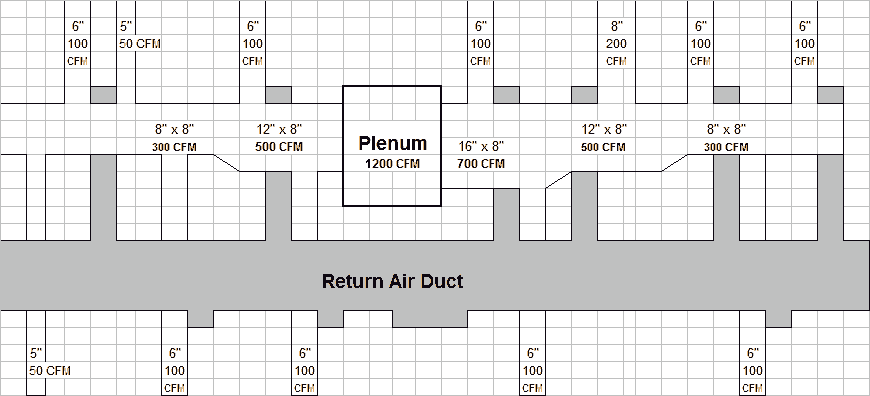

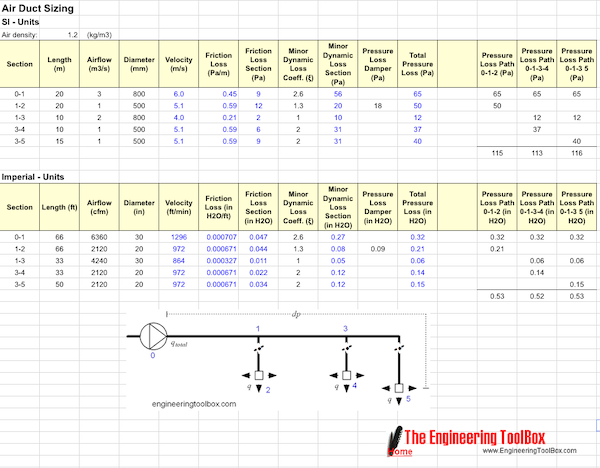

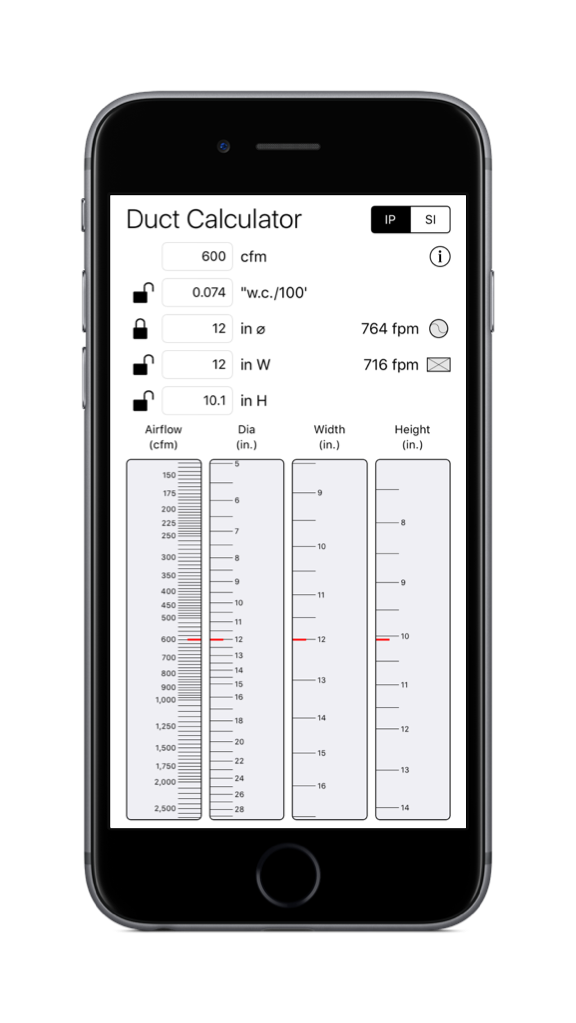

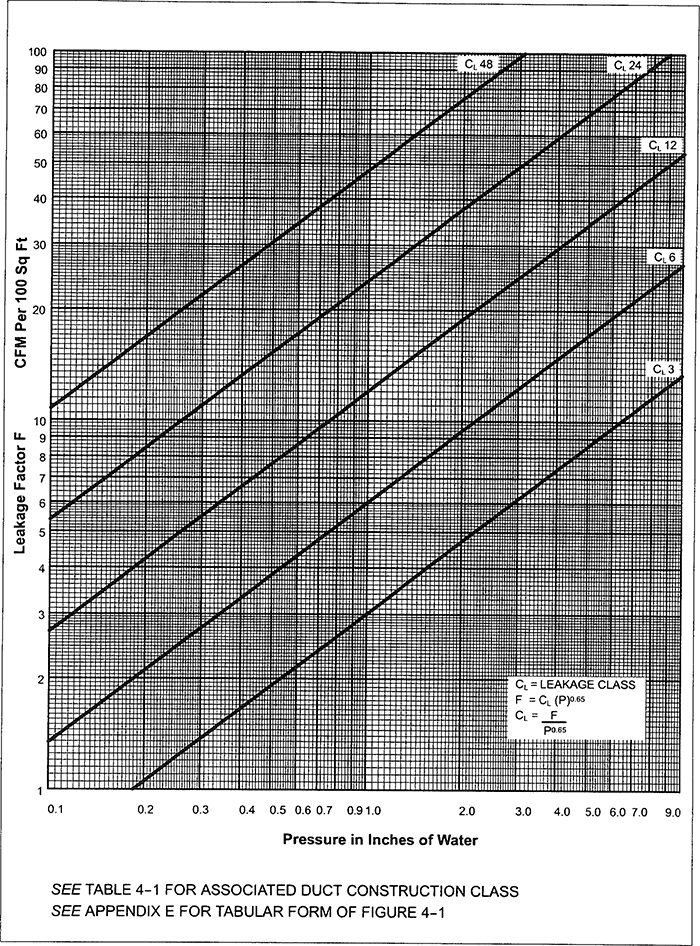

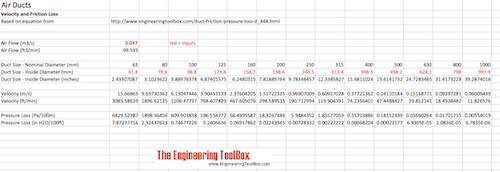

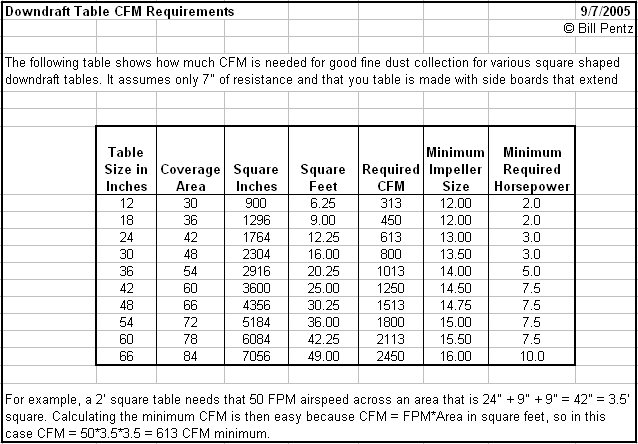

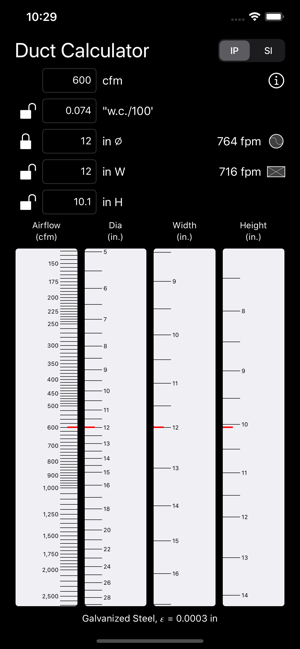

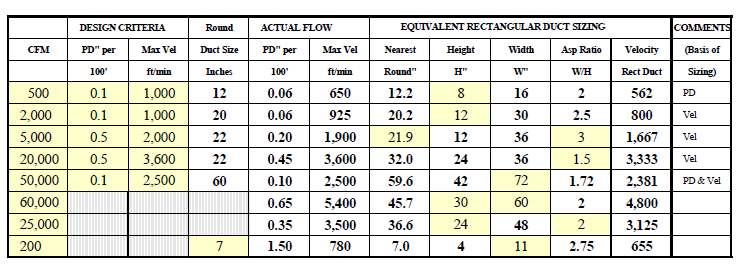

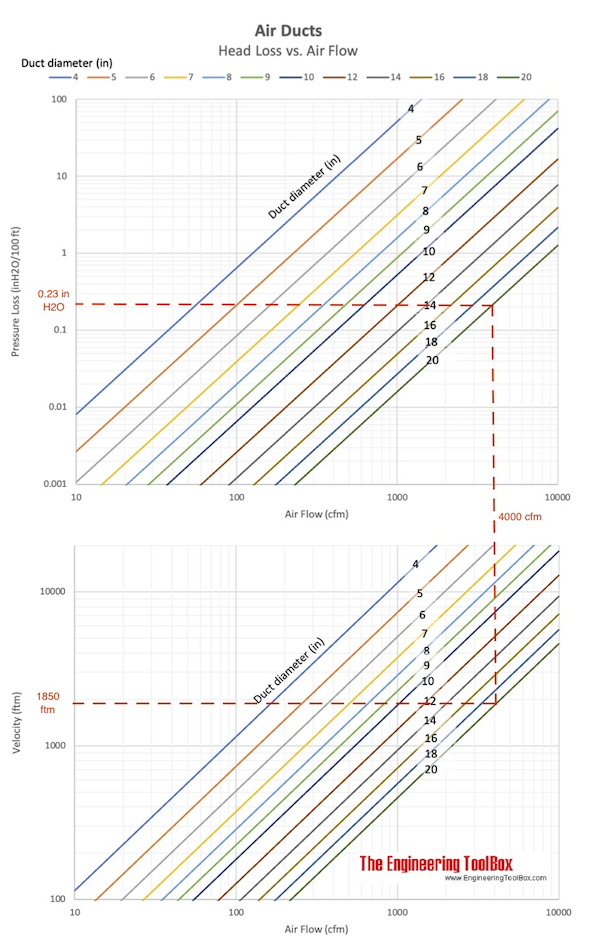

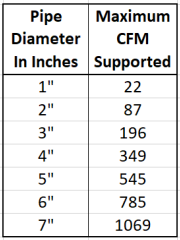

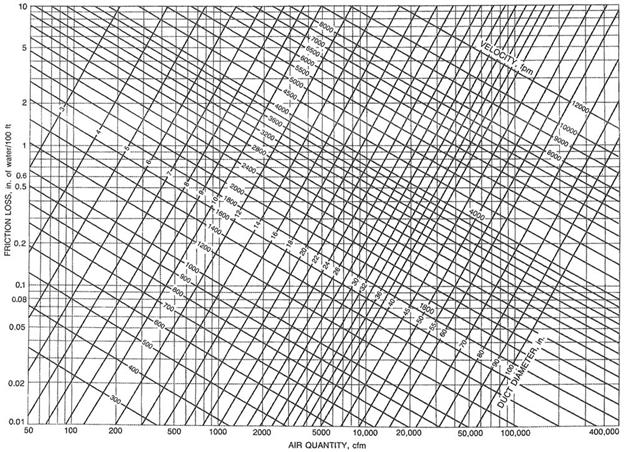

Round duct cfm chart. Read friction loss inches of water and duct velocity fpm. The rectangular dimensions and the air flow volume are adapted to the equal friction loss. For instance a 2 5 ton system approximately 400 cfm per ton would require 2 14 flexible return ducts or 1 very short flexible 18 duct to move the 1000 cfm required by the 2 5 ton system.

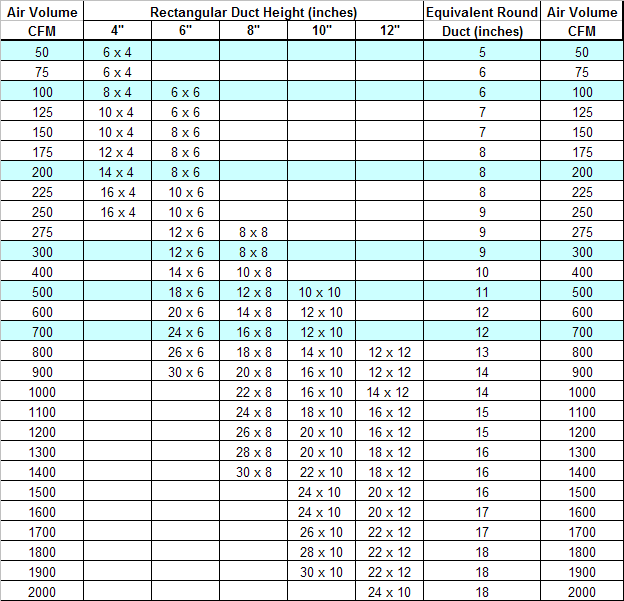

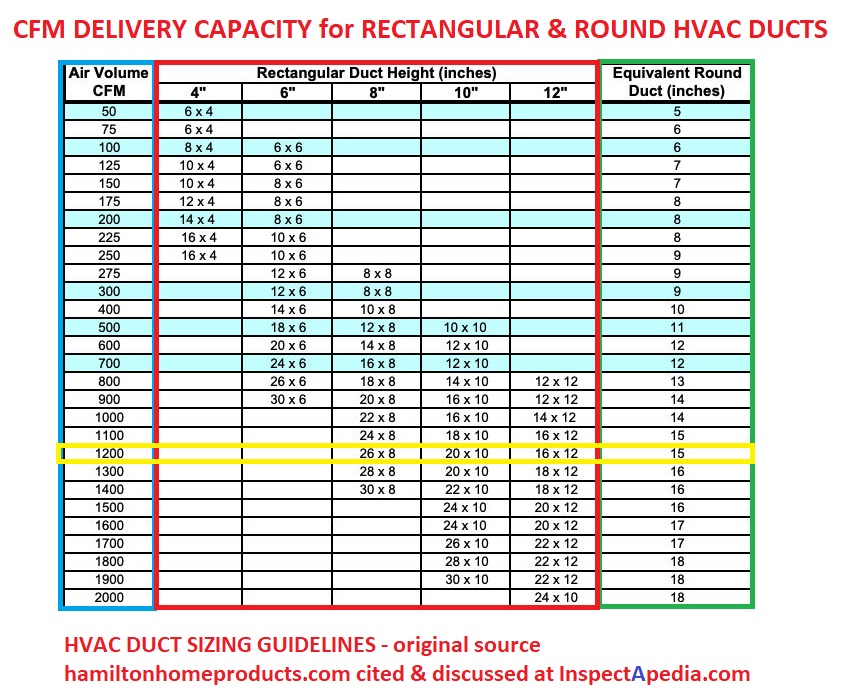

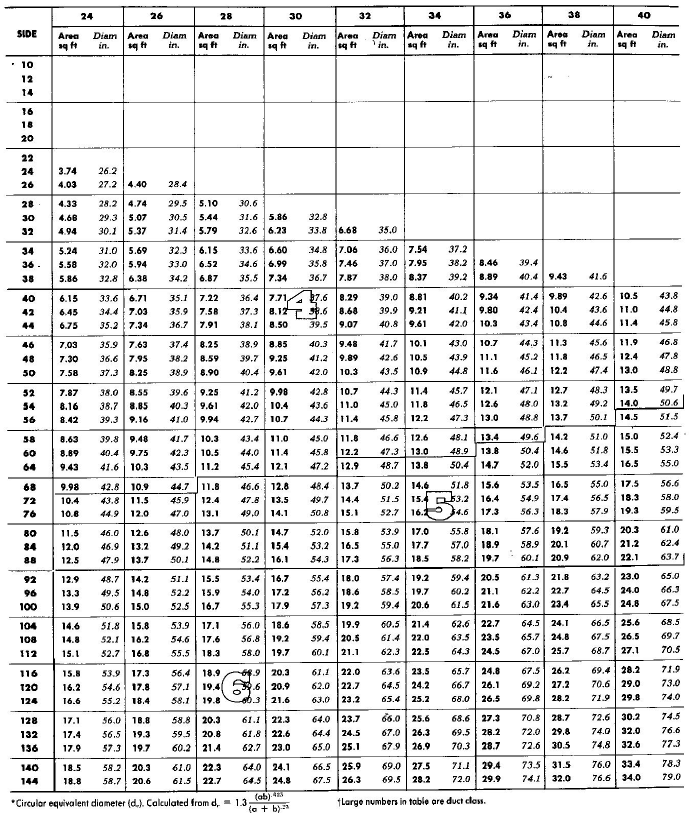

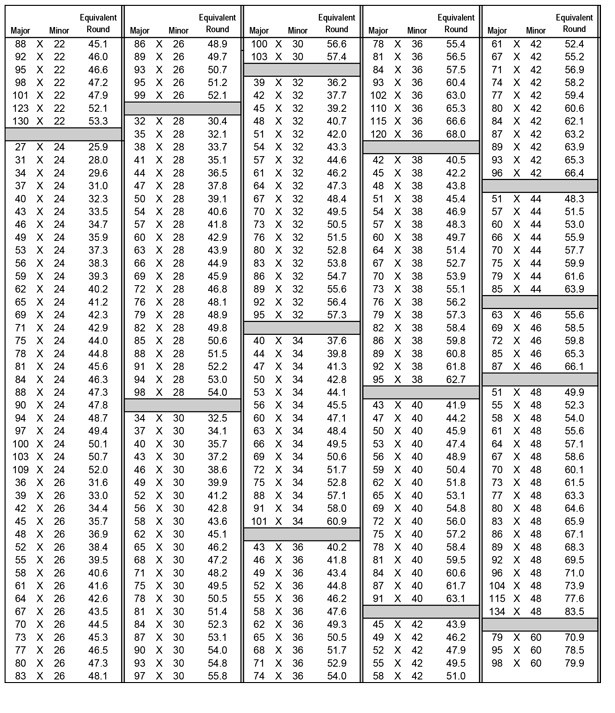

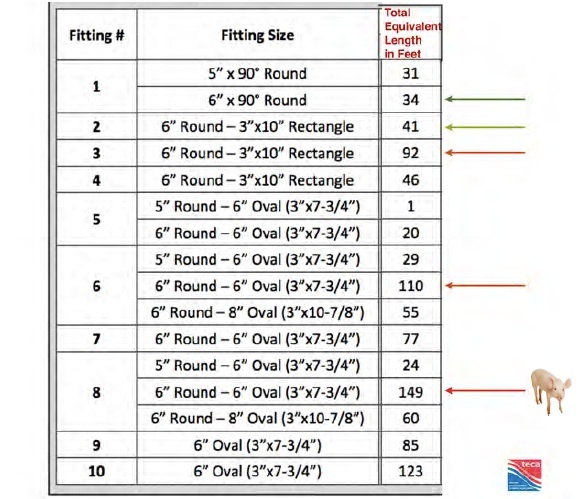

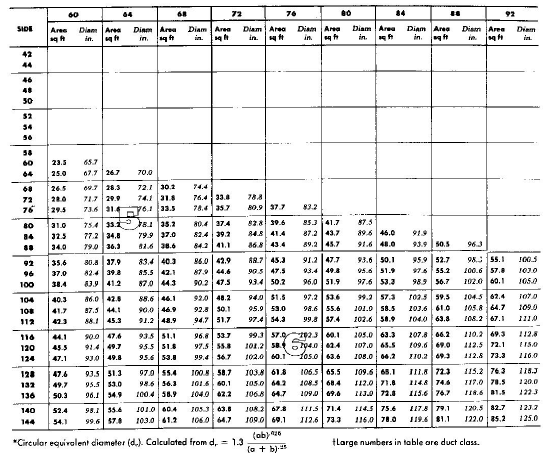

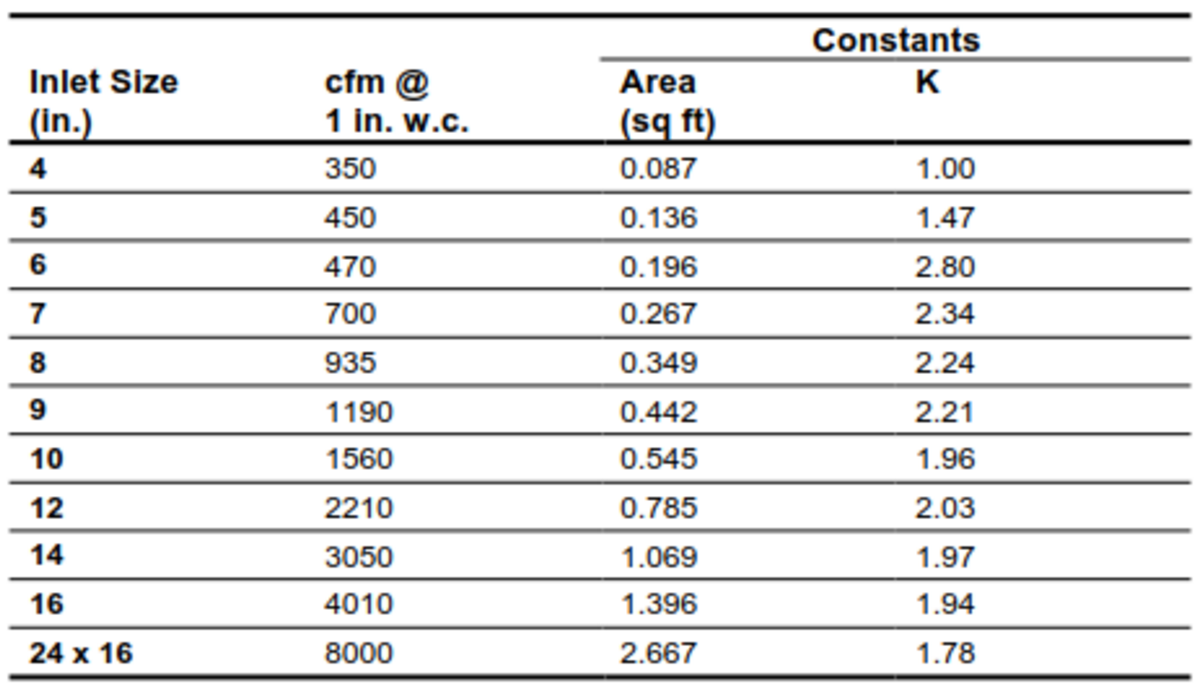

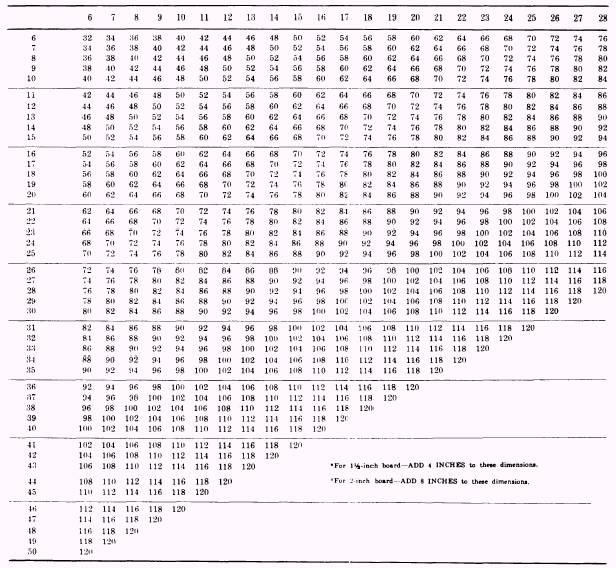

S5 round to round adjustable 20 25 el no. Air volume equivalent round air volume cfm 4 6 8 10 12 duct inches cfm 50 6 x 4 550 75 6 x 4 675 100 8 x 4 6 x. Wxh wxh wxh wxh wxh wxh wxh wxh 80 8x4 90 8x4 100 6 6x6 7x5 9x4 125 7x6 8x5 10x4 150 8x6 9x5 11x4 175 7 7x7 9x6 11x5 13x4 200 8x8 8x7 9x6 12x5 15x4.

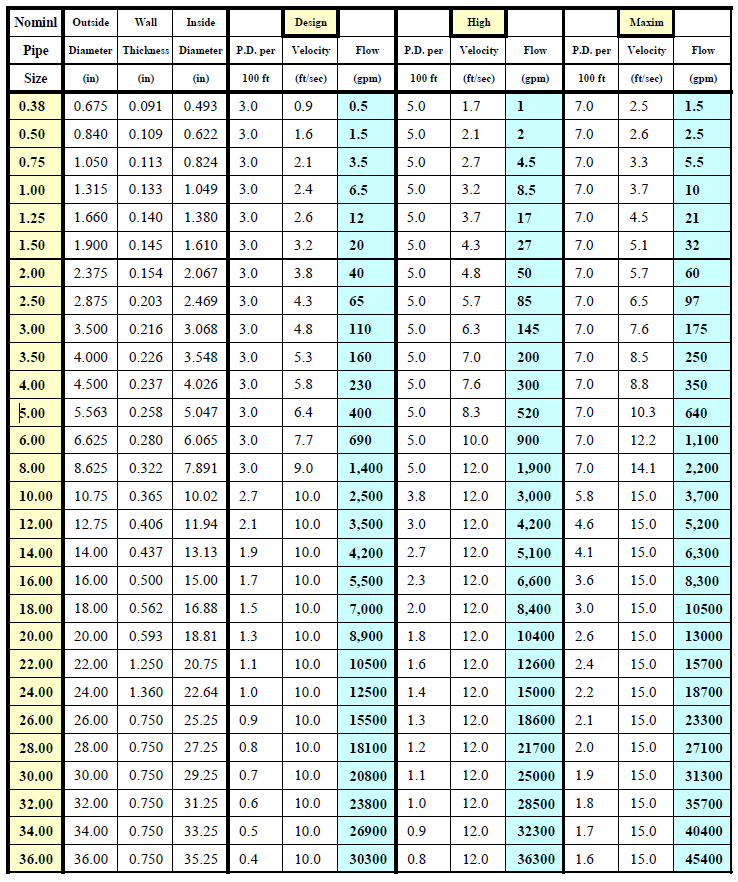

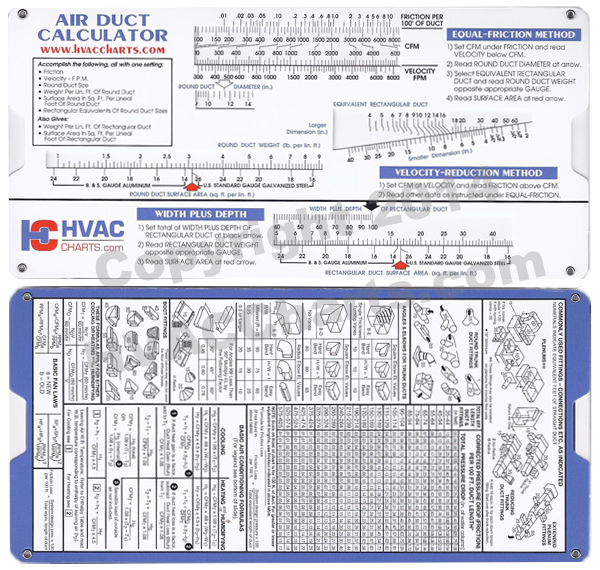

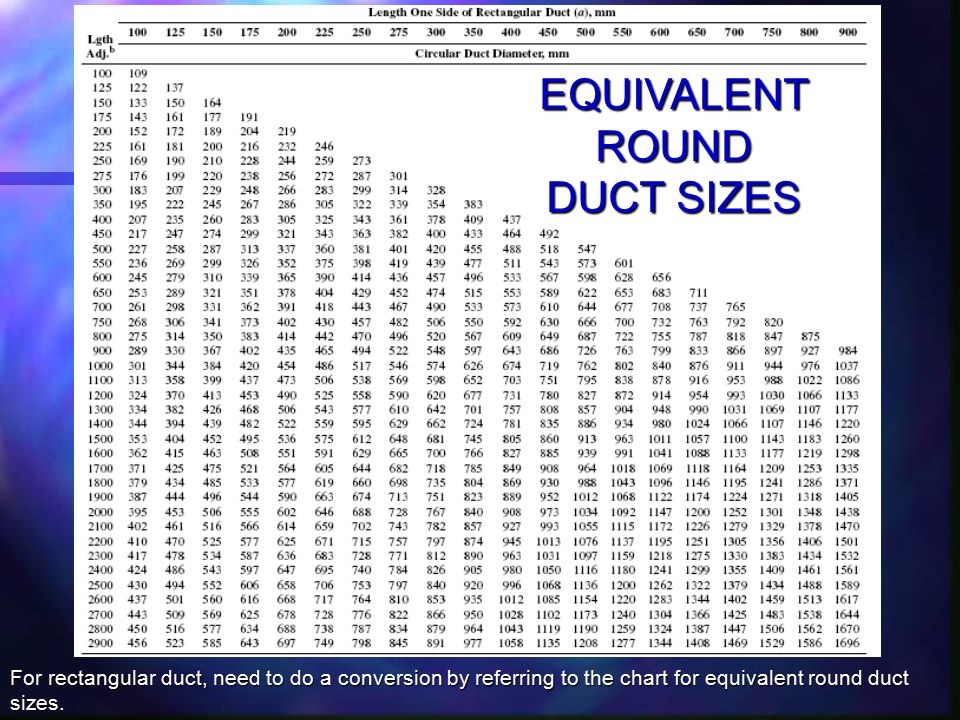

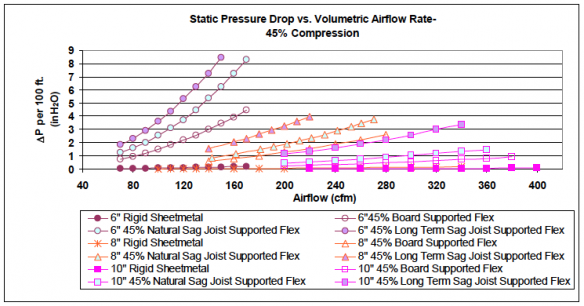

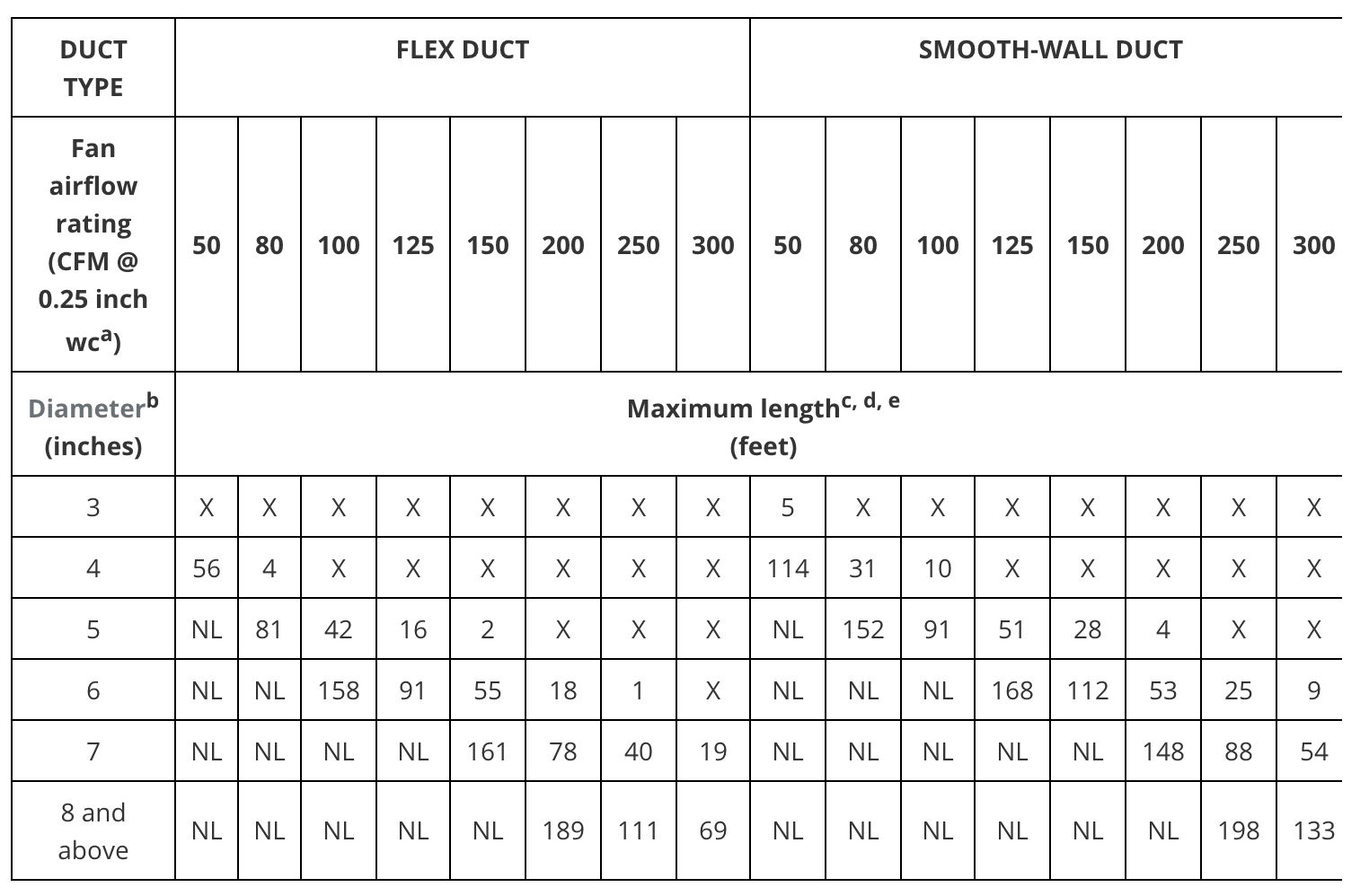

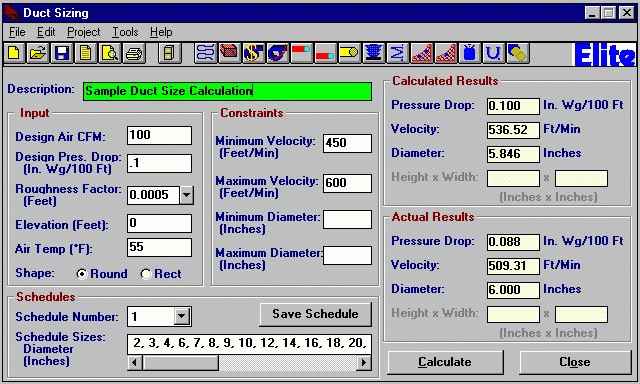

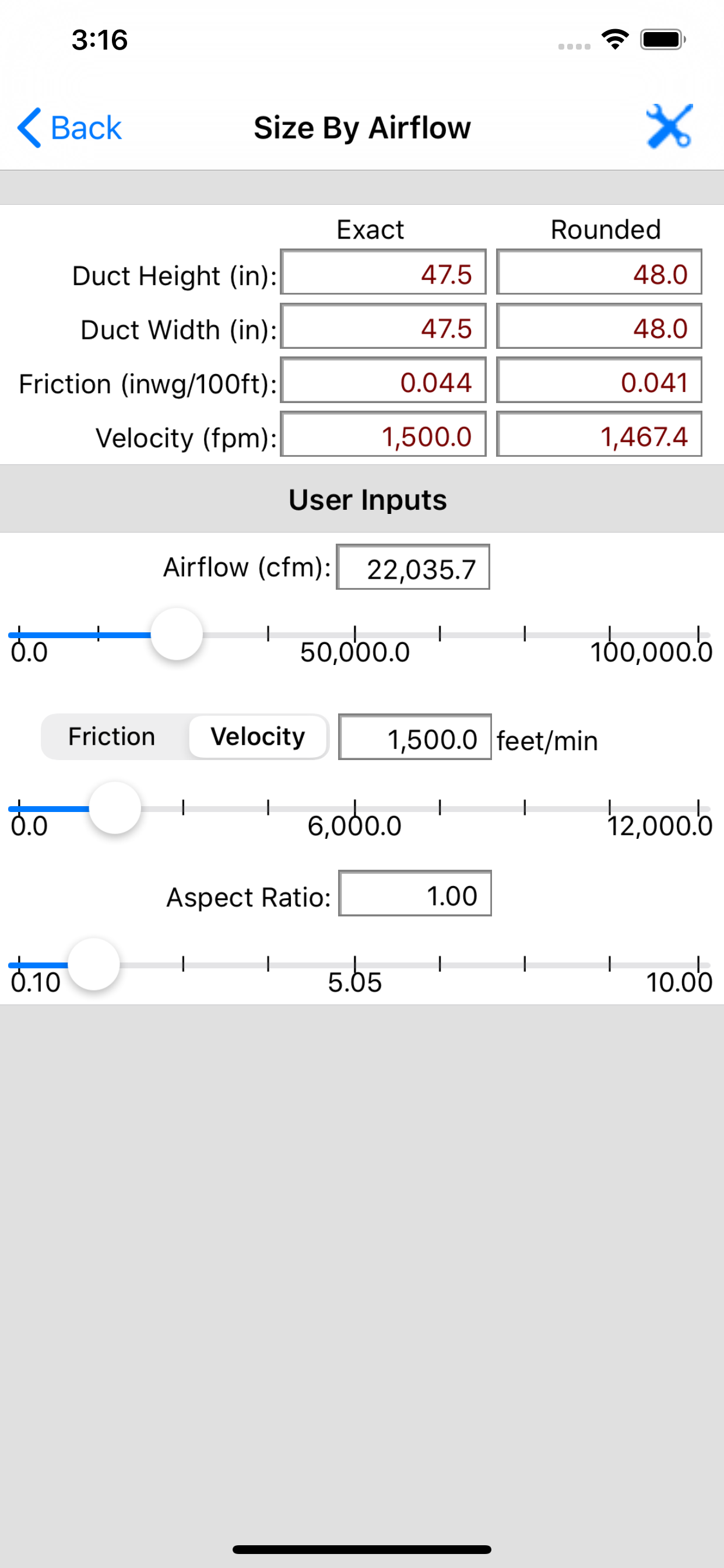

Enter the length of the rectangular duct. Equivalent round duct diameter. Flex duct 05 on most metal duct calculator round metal pipe 06 on most metal duct calculators field duct sizing chart rectangular sheet metal duct 07 on most metal duct calculators.

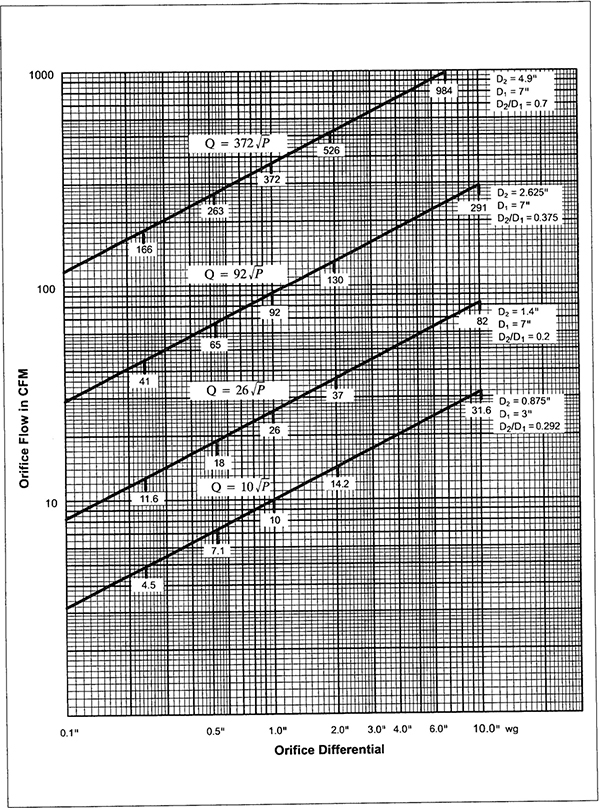

Read round duct diameter inches and friction loss per 100 of duct inches of water. Enter duct airflow cfm duct velocity fpm duct length and the number of bends. 97 round starting collar 35 el no.

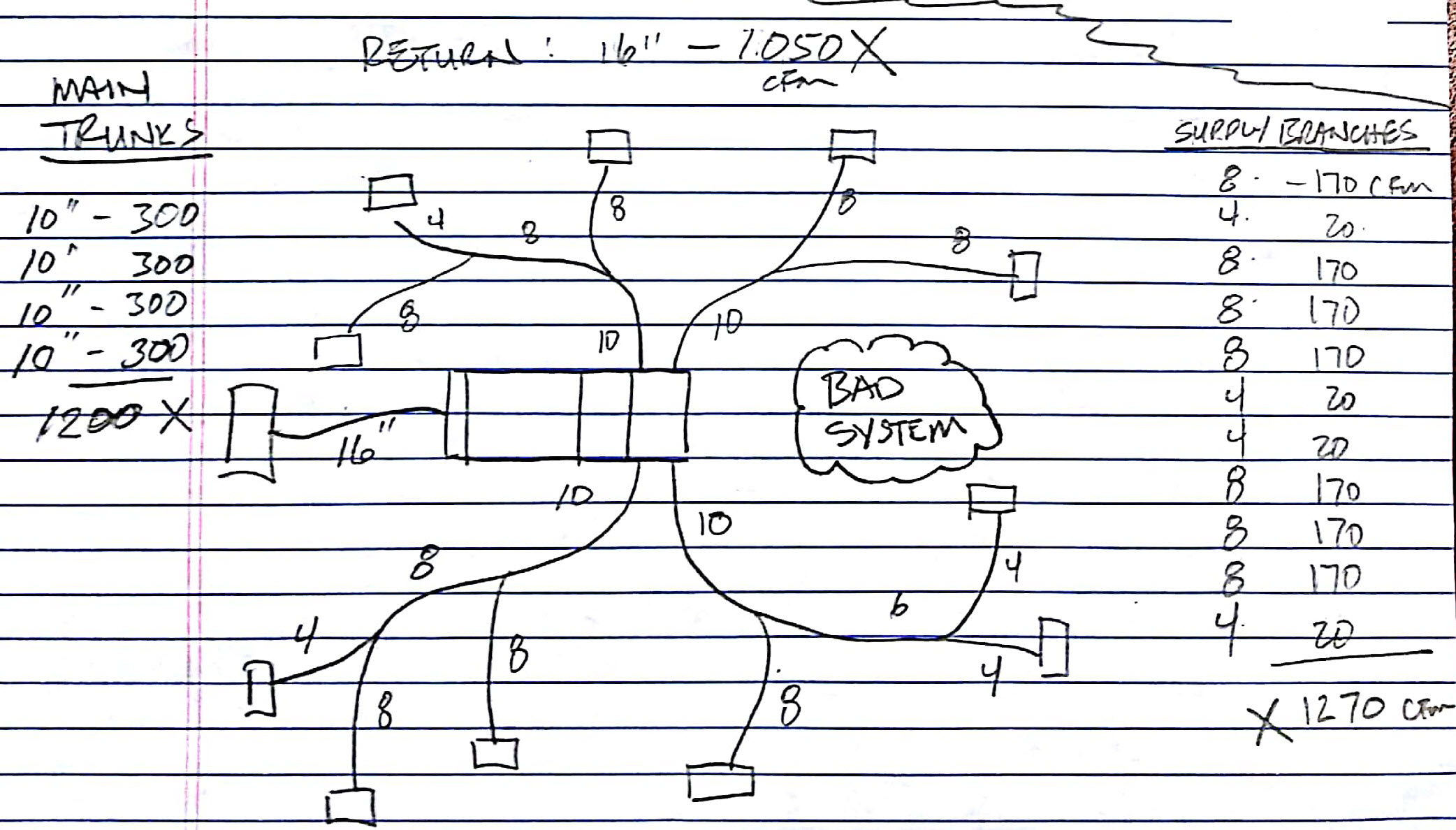

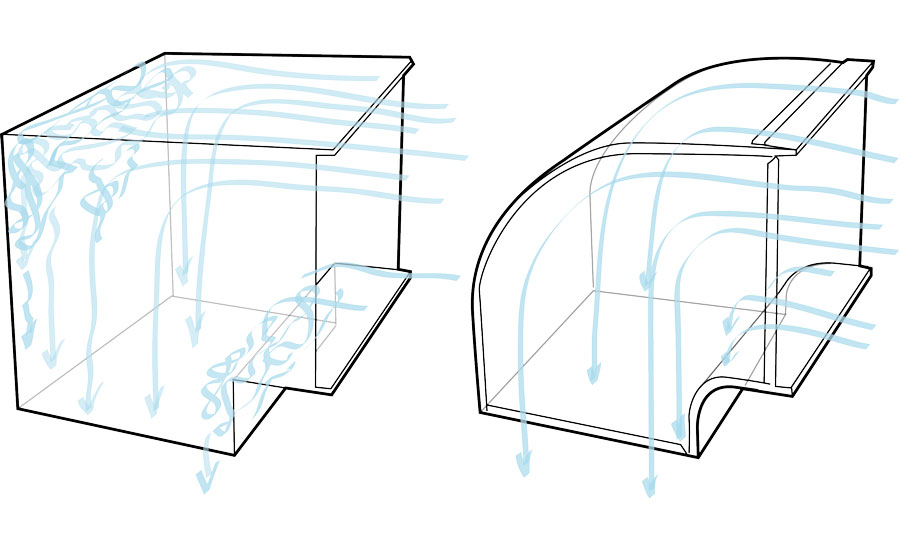

As systems increase in efficiency the tolerances of how we have always done it will no longer be adequate. The table is based on the ducts friction loss formula. 62 square to round elbow 40 el no.

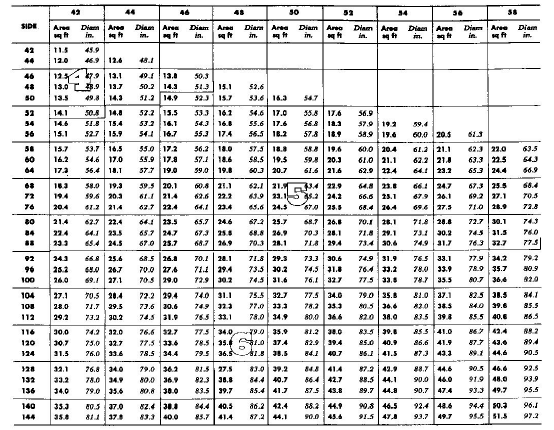

The table below can be used to compare equivalent diameters for rectangular and round circular ducts. 63a square to round elbow 40 45 el no. Sheet metal duct friction loss calculator.

This equal friction method of duct sizing should be adequate for normal residential furnace heating and air conditioning applications. Round fittings takeoffs no. Enter round duct diameter inches duct airflow cfm duct length and the number of bends.

Ductulator velocity 576 air flow in cfm 3 14 diameter 2 when diameter is given ductulator velocity 576 a side1 side2 4 when sides are given ductulator velocity air flow in cfm cross sectional area when area is given. Larger volumes or higher static pressures should be dealt with on an individual job basis. Enter round duct diameter.

Enter the desired length of the rectangular duct. 65 round to round 20 25 el duct elbows radius throat no. 14 up to 11 10 el 12 to 21 15 el.